News

Site Editor

Site

https://cdn.anyhz.com/uploads/image/653decbc2fb16.png

The application of frequency converters in steelmaking dust removal fans not only effectively solves many drawbacks of traditional speed regulation methods, but also achieves significant energy-saving effects by precisely controlling the air volume. The system after the transformation is more stable, the equipment life is extended, and the maintenance cost is reduced, while providing strong support for the sustainable development of the enterprise. In the future, with the continuous advancement of technology, the application of frequency converters in more industrial fields will bring greater value to energy conservation, emission reduction and green production.

Site

https://cdn.anyhz.com/uploads/image/653decbc2fb16.png

The application of frequency converters in steelmaking dust removal fans not only effectively solves many drawbacks of traditional speed regulation methods, but also achieves significant energy-saving effects by precisely controlling the air volume. The system after the transformation is more stable, the equipment life is extended, and the maintenance cost is reduced, while providing strong support for the sustainable development of the enterprise. In the future, with the continuous advancement of technology, the application of frequency converters in more industrial fields will bring greater value to energy conservation, emission reduction and green production.

Application Case of Frequency Converter on Steelmaking Dust Removal Fan

Views: 1845

Author: Site Editor

Publish Time: 2025-02-18

Origin: Site

Introduction: With the continuous development of industrial technology and increasingly stringent environmental protection requirements, the steel industry faces the dual challenges of energy conservation and emission reduction and sustainable development. The large amount of flue gas generated during steelmaking not only pollutes the environment, but also poses a potential threat to the health of equipment and personnel. Therefore, the use of high-efficiency and energy-saving frequency conversion transformation to optimize the dust removal system has become an inevitable choice for steel mills. The frequency converter can significantly reduce energy consumption and improve the stability and reliability of the system by accurately controlling the motor speed.

Before transformation

In the converter dust removal system of a steel mill, the dust removal fan uses a traditional hydraulic coupler for speed regulation. However, this speed regulation method has many problems: poor control accuracy, narrow speed regulation range, low efficiency, and large losses during operation. In addition, the operating requirements of the fan at different process stages vary greatly, and the hydraulic coupler is difficult to achieve precise air volume regulation, resulting in serious energy waste. For example, high air volume is required in the oxygen blowing stage, while the air volume demand is low in the iron addition, temperature measurement, steel tapping and other stages. The traditional speed regulation method cannot flexibly adapt to these changes.

Design plan

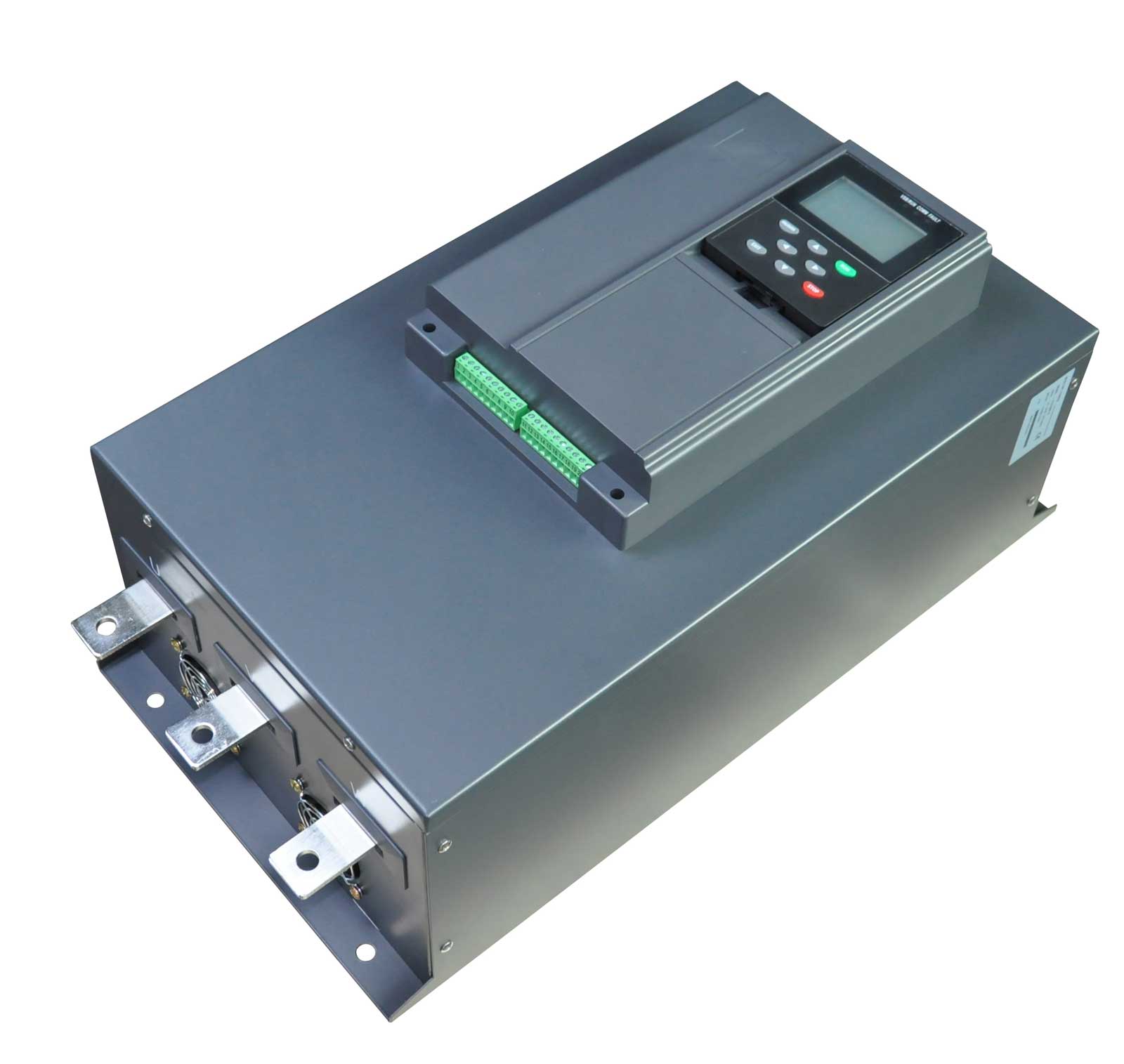

In order to achieve the goal of energy saving and consumption reduction and improve the system operation efficiency, the steel mill decided to carry out frequency conversion transformation on the dust removal fan. The transformation plan adopts ANYHZ FST series high-voltage frequency converter, which adjusts the air volume by changing the motor speed, so that the fan can achieve variable speed operation in different process stages. The specific plan is as follows:

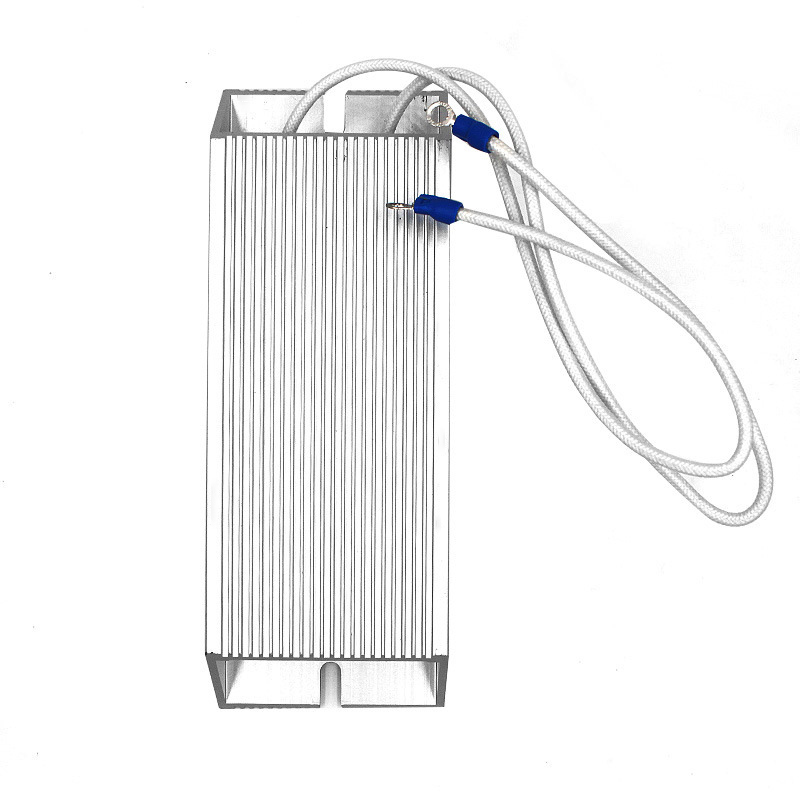

Equipment selection: According to the on-site load conditions, select ANYHZ FST high-voltage frequency converter, and configure a one-to-one manual bypass cabinet for switching between variable frequency and industrial frequency.

Operation mode: Two speed points are preset, corresponding to the high-speed and low-speed operation states of the fan. In the oxygen blowing stage, the fan runs at high speed; in other stages, the fan runs at low speed.

Control optimization: The frequency converter is equipped with an excellent human-machine interface, and the staff can adjust the parameters according to the actual working conditions to ensure the dust removal effect.

Economic benefits after transformation

After the transformation, the operating efficiency of the dust removal fan has been significantly improved, and the energy-saving effect is very obvious. The specific economic benefits are as follows:

Electricity saving benefits: Through frequency conversion speed regulation, the energy consumption of the fan at low speed is greatly reduced. According to statistics, the primary dust removal fan can save 611,250 yuan in electricity bills per year, and the secondary dust removal fan can save 500,000 yuan in electricity bills per year, with a total annual electricity saving of 1,111,250 yuan.

Equipment life extension: The soft start function of the inverter reduces the impact of the starting impact current on the motor and the power grid, effectively extending the service life of the motor. In addition, the original regulating damper is changed to a fully open state, which reduces the wear of the damper and reduces the cost of inspection and maintenance.

Investment recovery period: The total investment of the project is 980,000 yuan, and the investment recovery period is about 1.33 years. After the transformation, not only energy conservation and emission reduction are achieved, but also production costs are significantly reduced, and the economic benefits of the enterprise are improved.

Conclusion:

The application of frequency converters in steelmaking dust removal fans not only effectively solves many drawbacks of traditional speed regulation methods, but also achieves significant energy-saving effects by precisely controlling the air volume. The system after the transformation is more stable, the equipment life is extended, and the maintenance cost is reduced, while providing strong support for the sustainable development of the enterprise. In the future, with the continuous advancement of technology, the application of frequency converters in more industrial fields will bring greater value to energy conservation, emission reduction and green production.

Contact Us

Contact Us