News

Site Editor

Site

https://cdn.anyhz.com/uploads/image/653decbc2fb16.png

The application of frequency converters in kowtow machines not only improves energy efficiency and reduces operating costs, but also enhances equipment reliability and environmental sustainability, achieving a win-win situation of economic and environmental benefits.

Site

https://cdn.anyhz.com/uploads/image/653decbc2fb16.png

The application of frequency converters in kowtow machines not only improves energy efficiency and reduces operating costs, but also enhances equipment reliability and environmental sustainability, achieving a win-win situation of economic and environmental benefits.

Application case of frequency converter on kowtow machine

Views: 2042

Author: Site Editor

Publish Time: 2023-11-23

Origin: Site

Introduction: The prospect of

frequency converter transformation of kowtow machines is positive, because it can significantly improve energy efficiency, reduce costs, and conform to the development trend of green energy conservation, and the market demand continues to grow.

Before transformation:

The kowtow machine, also known as the oil pumping unit, is a traditional equipment used to extract crude oil in oil fields. Before the frequency converter transformation, the kowtow machine usually adopts AC asynchronous motor driven by pulley. This driving mode makes the motor run at a constant speed and cannot adjust the running speed according to the actual oil output of the oil well. This leads to high energy consumption and low efficiency, and causes a large impact on the motor and mechanical equipment at startup, shortening the service life of the equipment.

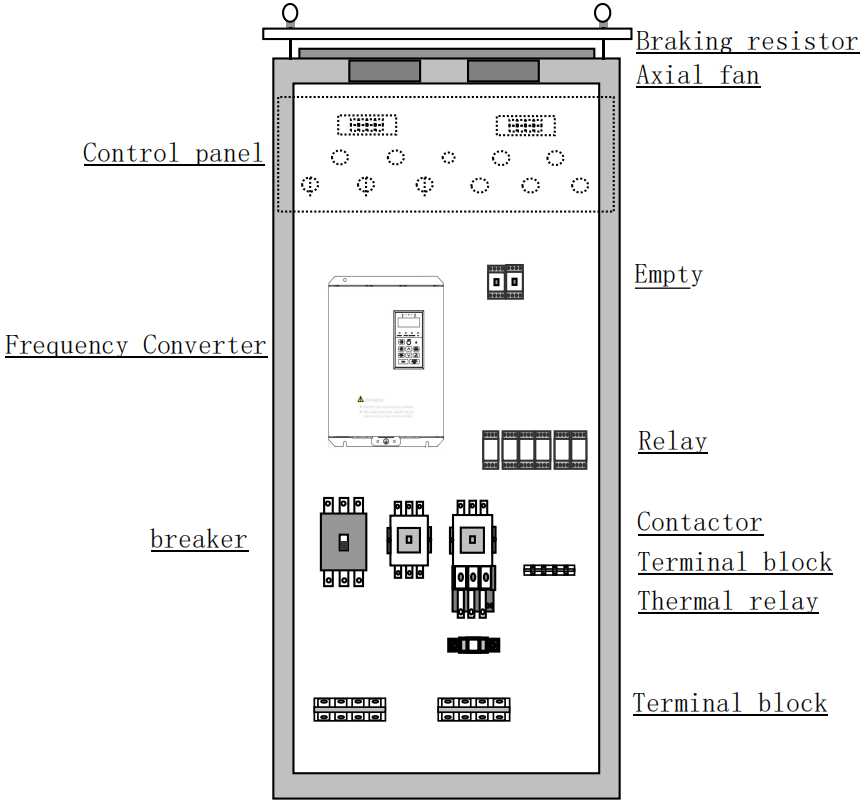

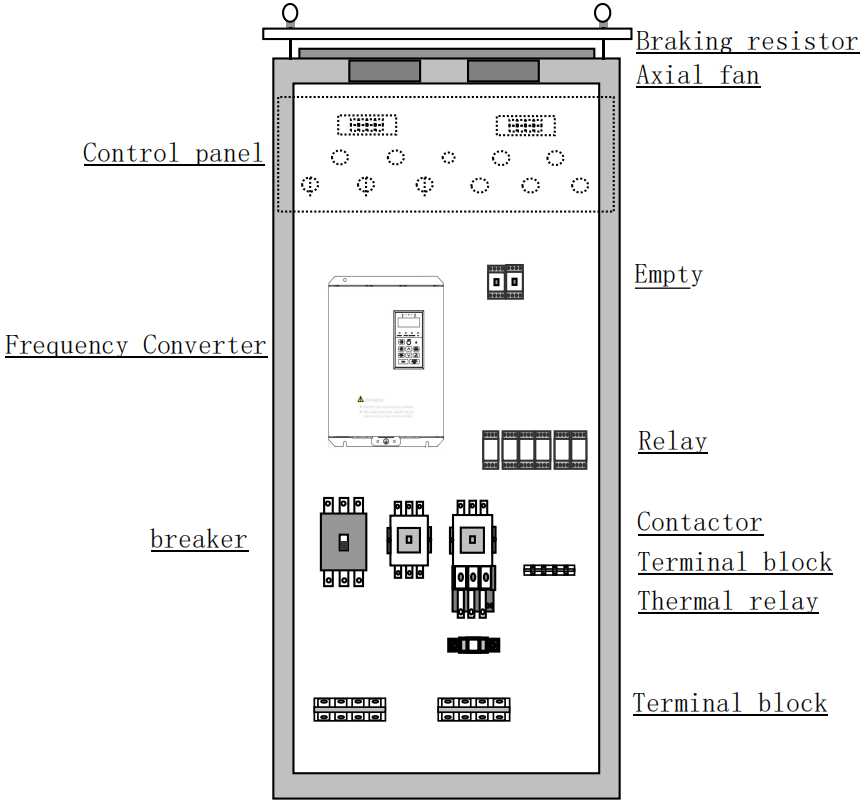

Transformation design:

Since the oil pumping unit works in the field in a harsh environment, and many oil wells are unattended, high requirements are placed on the reliability and environmental adaptability of the energy-saving equipment.

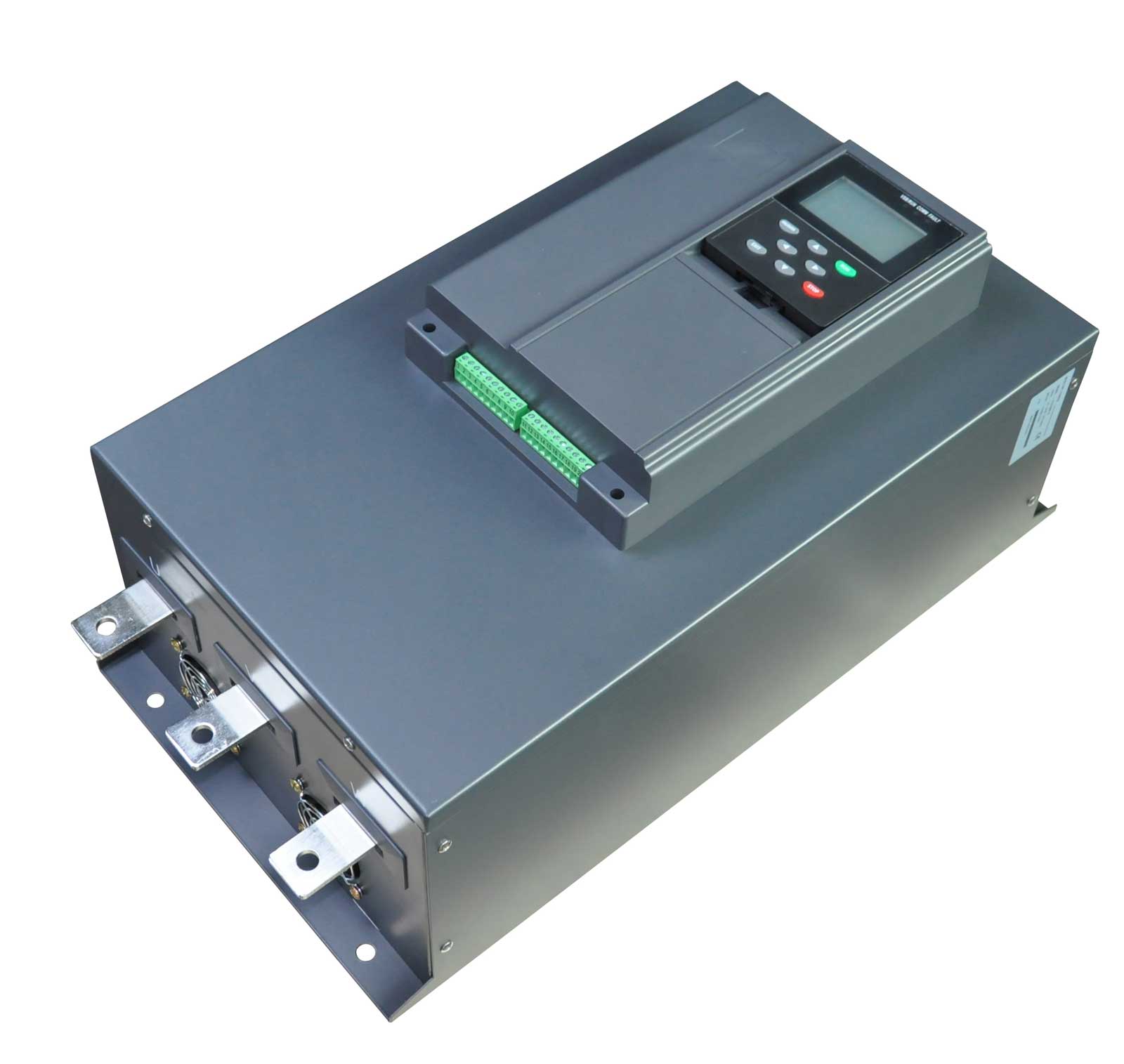

1. The FST-650L series frequency converter has a wide applicable temperature range, and the allowable ambient temperature is -10~50℃.

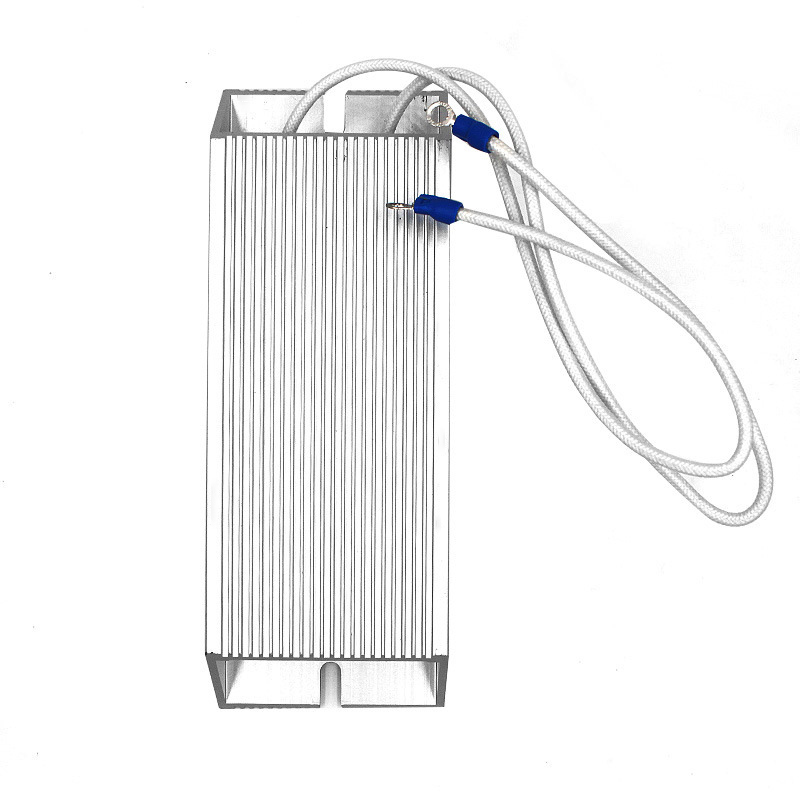

2. The FST-650L series can be used conveniently by simply adding a brake component;

3. The overload capacity of the FST-650L series is 110%/60 seconds and 150%/3 seconds; in order to fully meet the requirements of the load-changing working conditions of the kowtow machine, it is enlarged by one level;

4. The protection and diagnostic functions of the FST-650L series make the system operation safer and more reliable, and it is easier to troubleshoot the fault when a fault occurs, minimizing the fault time;

5. The eight-speed function of the FST-650L series can easily realize frequency prefabrication, such as: setting two proximity switches K1 at the corresponding parts of the kowtow machine, and K2 is connected to the 5# and 6# terminals of the inverter. When K2 is turned on, the piston rises and the motor runs at 65Hz until K1 is turned on, and the motor runs at 35Hz, causing the piston to fall.

Early Effects:

In the early wells, due to the recent exploitation, the oil reserves are large. By increasing the speed, the frequency converter runs at 65Hz, the frequency is increased by 1/3, and the motor speed is increased by 30%. The oil production is also increased accordingly. The comprehensive oil production rate can produce 20% more oil than the power frequency, and the work efficiency is increased by 1.2 times, which is very popular among oil field workers.

Mid- and late-stage effects:

In the mid- and late-stage wells, due to the reduction of well reserves, if the motor is still running at the power frequency, it will inevitably waste electric energy and cause unnecessary losses. Therefore, we adopt the method of reducing the speed and stroke. Generally, the frequency of the frequency converter is operated between 35 and 40Hz, so that the motor speed is reduced by 30%. In addition, the oil production equipment is generally lightly loaded, and the power saving rate can reach about 25%.

Energy-saving principle:

What are the main aspects of energy saving:

1. The power factor can be increased from 0.4~0.5 to above 0.9, which can play the function of ordinary "energy saver" - power factor compensation, and also save the power supply bureau from fines due to low power factor.

2. Reduce output current when the load is low. The original system motor runs at a constant 50HZ. When the counterweight drops, the current is large, and the efficiency and power factor of the motor are very low, resulting in a huge waste of electric energy. After using the inverter, the inverter can separate the excitation current (reactive current) and the torque current (active current), and reduce the output current when the load is low, thereby achieving energy saving.

3. The energy saving of the inverter can reach more than 25%. In the middle and late stages of oil production, the permeability of the oil well deteriorates. At this time, if the motor is still running at a speed of 50HZ, it will inevitably cause a lot of waste. At this time, the inverter is used to appropriately reduce the speed of the motor, so that the equipment and the industry and mining can cooperate well to achieve energy saving.

In summary, the energy saving of the frequency converter can reach more than 25%

Energy saving effect calculation:

For a 7.5KW motor:

Electricity saving per day: 7.5×24×0.25=75 degrees

Electricity saving per day: 75×0.8=60 yuan

Electricity saving per year: 60×365=21900 yuan

For a 30KW motor:

Electricity saving per day: 30×24×0.25=180 degrees

Electricity saving per day: 180×0.8=144 yuan

Electricity saving per year: 144×365=52560 yuan

Conclusion:

In summary, the application of frequency converters in kowtow machines not only improves energy efficiency and reduces operating costs, but also enhances equipment reliability and environmental sustainability, achieving a win-win situation of economic and environmental benefits.

Contact Us

Contact Us