News

Site Editor

Site

https://cdn.anyhz.com/uploads/image/653decbc2fb16.png

Frequency converters, also known as variable frequency drives (VFDs), are essential components in modern industrial and commercial applications.

Site

https://cdn.anyhz.com/uploads/image/653decbc2fb16.png

Frequency converters, also known as variable frequency drives (VFDs), are essential components in modern industrial and commercial applications.

In What Ways Can Frequency Converters Improve Motor Performance?

Views: 1817

Author: Site Editor

Publish Time: 2024-08-21

Origin: Site

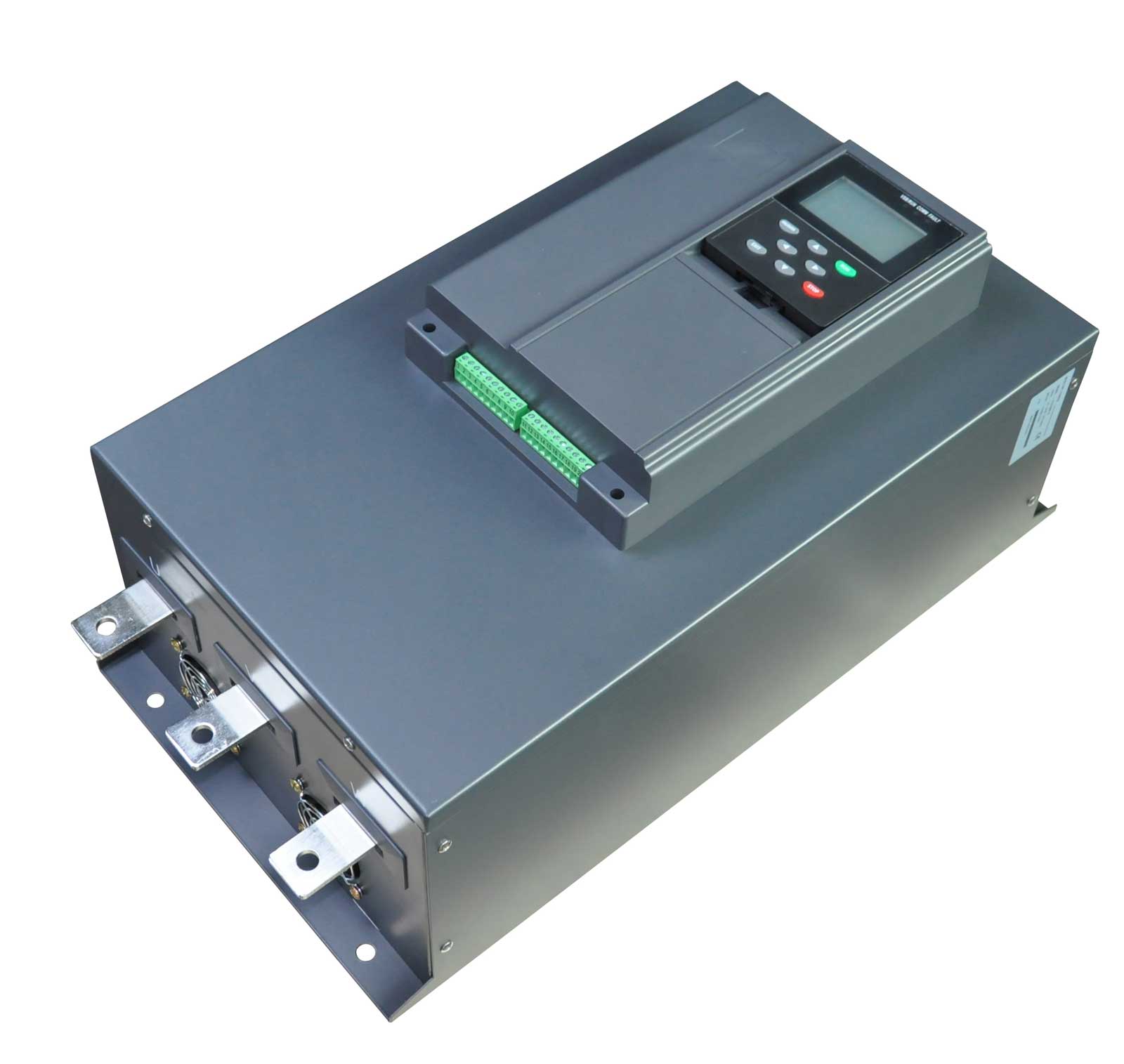

Frequency converters, also known as variable frequency drives (VFDs), are essential components in modern industrial and commercial applications. They control the speed and torque of electric motors by varying the frequency and voltage of the power supplied to the motor.This article explores the various ways frequency converters can enhance motor performance, contributing to improved efficiency, reliability, and overall operational effectiveness.

1. Precise Speed Control

One of the primary benefits of frequency converters is their ability to provide precise speed control. By adjusting the frequency of the electrical supply, VFDs allow motors to operate at various speeds, tailored to the specific needs of the application. This precision is particularly valuable in processes that require variable speeds, such as conveyors, fans, and pumps. The ability to fine-tune motor speed enhances process control, improves product quality, and reduces wear and tear on mechanical components.

2. Energy Efficiency

Frequency converters contribute significantly to energy efficiency by matching motor speed to the actual demand of the application. In traditional systems, motors often run at a constant speed regardless of the required output, leading to unnecessary energy consumption. VFDs, on the other hand, adjust the motor speed to match the load requirements, reducing energy waste. This energy-saving capability not only lowers operational costs but also supports environmental sustainability by reducing the carbon footprint.

3. Soft Start and Stop

Directly starting and stopping motors can cause mechanical stress and electrical surges, leading to premature wear and potential damage. Frequency converters provide a soft start and stop feature, gradually ramping up or down the motor speed. This gentle acceleration and deceleration reduce the mechanical stress on the motor and connected equipment, extending their lifespan and minimizing maintenance requirements. Additionally, soft starting prevents electrical surges, protecting the motor and the electrical network.

4. Improved Process Control

In applications where precise control of speed, torque, and position is critical, frequency converters excel by offering advanced control capabilities. VFDs enable accurate control of motor speed and torque, ensuring optimal performance in processes such as material handling, packaging, and machining. Enhanced process control leads to higher productivity, better product quality, and reduced downtime due to fewer process interruptions.

5. Reduced Mechanical Wear

By providing smooth and controlled motor operation, frequency converters help reduce mechanical wear on motors and connected equipment. The ability to adjust motor speed and torque to match the load requirements minimizes the mechanical stresses associated with sudden starts and stops. This reduction in wear and tear results in longer equipment life, lower maintenance costs, and increased operational reliability.

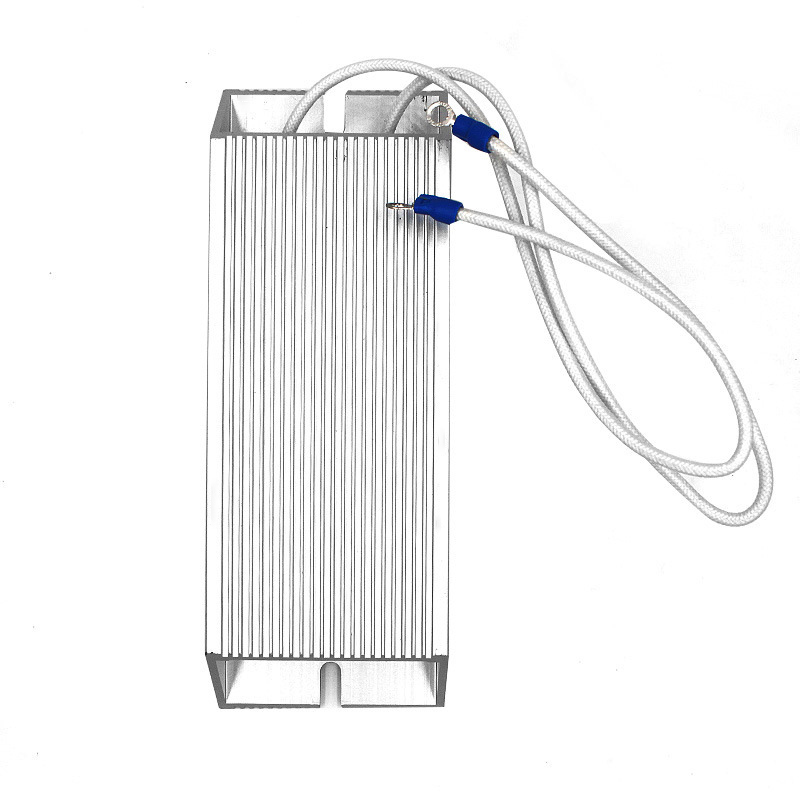

6. Enhanced Motor Protection

Modern frequency converters are equipped with various protection features that safeguard motors from potential damage. These features include overload protection, overvoltage and undervoltage protection, and protection against short circuits and ground faults. By continuously monitoring motor parameters and operating conditions, VFDs can detect and respond to abnormal situations, preventing damage and ensuring safe operation.

7. Noise Reduction

Frequency converters can significantly reduce motor noise by enabling smooth and controlled operation. Traditional motors running at constant speeds often produce noise due to mechanical vibrations and sudden starts and stops. VFDs minimize these vibrations by providing gradual acceleration and deceleration, resulting in quieter motor operation. This noise reduction is particularly beneficial in applications where a quiet environment is essential, such as HVAC systems and office buildings.

8. Flexibility and Adaptability

Frequency converters offer flexibility and adaptability in various applications by allowing motors to operate at different speeds and torques. This adaptability makes it possible to use the same motor for multiple tasks, reducing the need for different motors for different applications. The ability to adjust motor performance to match changing operational requirements enhances overall system flexibility and efficiency.

Conclusion

Frequency converters play a crucial role in improving motor performance by providing precise speed control, enhancing energy efficiency, enabling soft starts and stops, improving process control, reducing mechanical wear, enhancing motor protection, reducing noise, and offering flexibility and adaptability. These benefits make VFDs an indispensable component in modern industrial and commercial applications.

Anyhertz Drive as a leading manufacturer of high-end magnetic flux vector frequency converters, we are committed to developing advanced solutions that enhance motor performance and drive efficiency. By leveraging the capabilities of frequency converters, businesses can achieve greater operational efficiency, reduced costs, and improved reliability in their motor-driven systems.

Contact Us

Contact Us