News

Site Editor

Site

https://cdn.anyhz.com/uploads/image/653decbc2fb16.png

Choosing the right frequency converter requires a comprehensive consideration of application requirements, power and voltage range, control functions, brand reputation, cost, and budget.

Site

https://cdn.anyhz.com/uploads/image/653decbc2fb16.png

Choosing the right frequency converter requires a comprehensive consideration of application requirements, power and voltage range, control functions, brand reputation, cost, and budget.

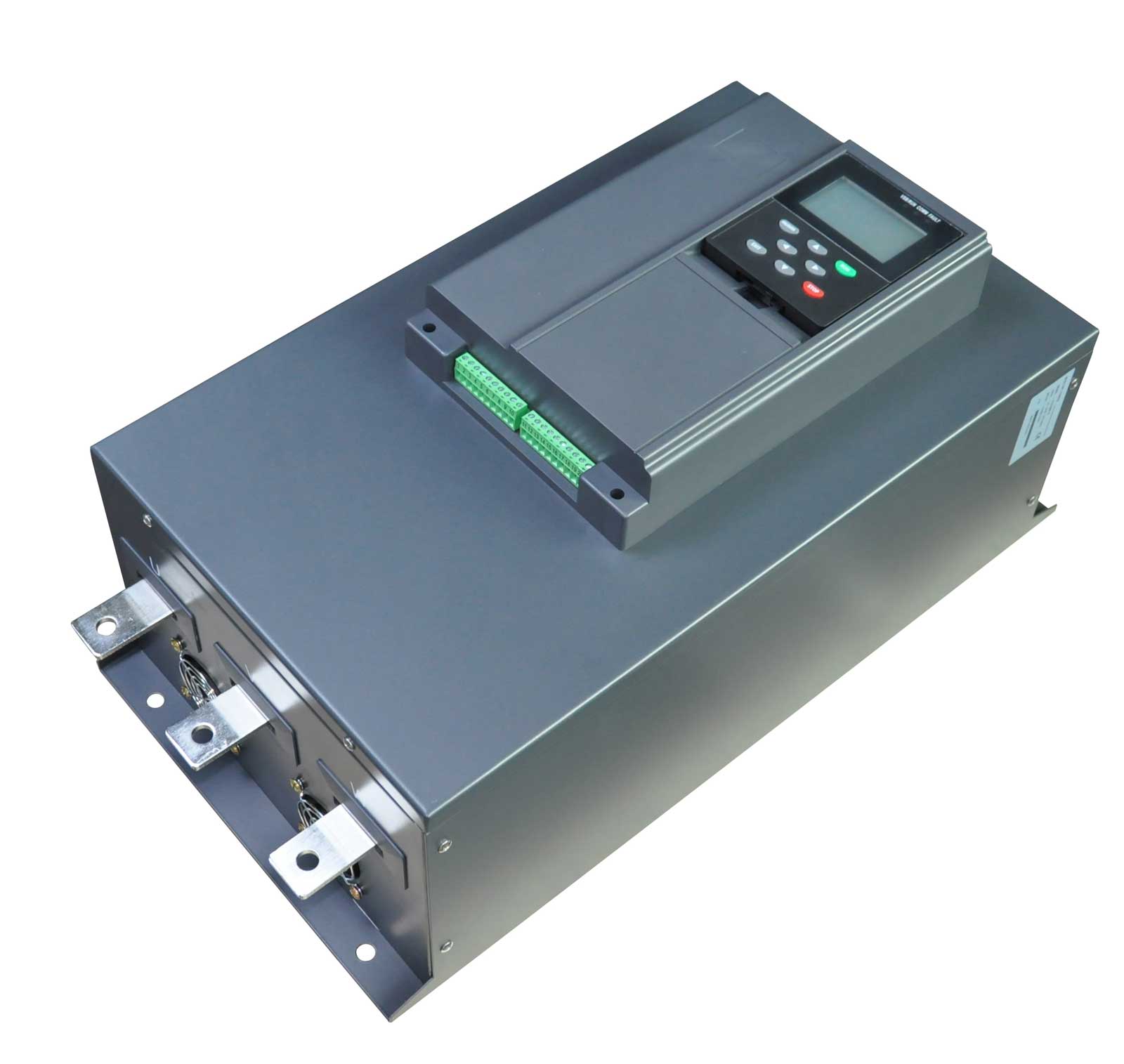

Technical Guide: How to Choose the Right Frequency Converter

Views: 2381

Author: Site Editor

Publish Time: 2025-03-26

Origin: Site

|

In the field of industrial automation and motor control, frequency converters (also known as VFDs - Variable Frequency Drives) are essential components. They not only regulate the speed of motors but also enhance the efficiency and reliability of systems. However, with a wide range of brands and models available on the market, selecting the right frequency converter can be a daunting task. This article provides some key suggestions to help you choose the most suitable frequency converter for your needs.

|

1. Determine Your Application Requirements

Before selecting a frequency converter, it is crucial to clarify your application requirements. Different applications may have varying demands on frequency converters. Here are some common application scenarios and their respective requirements:

-

Industrial Motor Control: If your application involves industrial motor control, you need to consider the power, voltage, frequency range of the motor, and whether high-precision speed control is required.

-

Energy-Saving Needs: For applications that require energy savings, such as fans and pumps, frequency converters can regulate motor speed to save energy.

-

Complex Process Control: In complex process control applications, such as papermaking and textile industries, frequency converters need to have high-precision speed control and fast response capabilities.

2. Choose the Right Power and Voltage Range

The power and voltage range of a frequency converter are key parameters when making a selection. You need to choose a frequency converter that matches the power and voltage of your motor. For example:

-

Power Range: Frequency converters come in a wide range of power capacities, from a few hundred watts to several thousand kilowatts. Ensure that the frequency converter's power capacity meets the maximum power demand of your motor.

-

Voltage Range: Common voltage ranges include 110V, 220V, 380V, etc. Select a frequency converter that matches the voltage of your motor.

3. Consider Control Functions

The control functions of a frequency converter directly affect its performance in real-world applications. Here are some important control functions to consider:

-

Speed Control Accuracy: For applications that require high-precision speed control, such as textile machinery, the speed control accuracy of the frequency converter is crucial.

-

Start and Stop Characteristics: Some applications require smooth starting and stopping, such as conveyor belt systems. The start and stop characteristics of the frequency converter must meet these requirements.

-

Overload Capability: In some cases, motors may encounter overload conditions. Frequency converters need to have a certain overload capacity to protect the motor from damage.

4. Choose the Right Brand and Model

There are many brands of frequency converters on the market, each with its own unique advantages and features. Selecting a reliable brand and the right model is key to ensuring long-term stable operation of your equipment. Here are some suggestions:

-

Brand Reputation: Choose well-known brands such as Anyhz Drive, which are known for their high-quality products and after-sales service.

-

Technical Support: Ensure that the brand you select can provide timely technical support and after-sales service, which is crucial for resolving any potential issues.

-

User Reviews: Check reviews and feedback from other users to understand the actual performance of the product.

5. Consider Cost and Budget

While cost is not the only factor to consider, it is important to take your budget into account when selecting a frequency converter. Here are some suggestions regarding cost:

-

Initial Investment: High-quality frequency converters are usually more expensive, but their reliability and performance can save you long-term maintenance costs.

-

Energy-Saving Benefits: Some frequency converters have energy-saving features that can save on energy costs over the long term.

-

Maintenance Costs: Choose frequency converters that are easy to maintain and repair to reduce long-term maintenance costs.

6. Installation and Commissioning

After selecting the right frequency converter, proper installation and commissioning are also very important. Here are some suggestions:

-

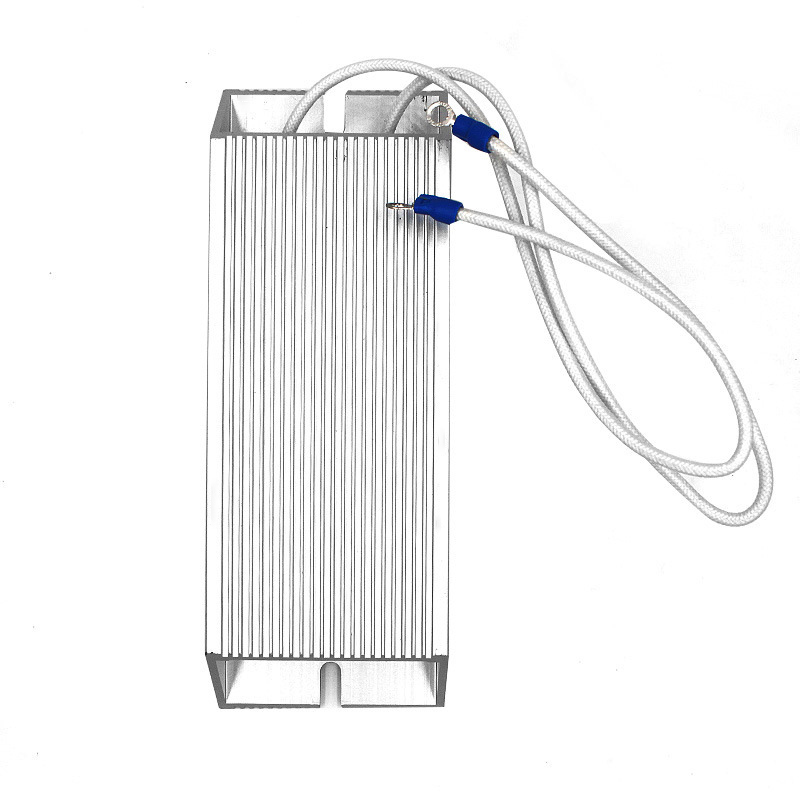

Installation Environment: Ensure that the frequency converter is installed in a dry, well-ventilated environment, avoiding high temperatures and humidity.

-

Correct Wiring: Follow the instructions to wire the frequency converter correctly, ensuring that the connections between the motor and the frequency converter are safe and reliable.

-

Commissioning Parameters: Set the parameters of the frequency converter correctly according to your actual application needs, such as speed, acceleration, overload protection, etc.

Summary

Choosing the right frequency converter requires a comprehensive consideration of application requirements, power and voltage range, control functions, brand reputation, cost, and budget. By carefully evaluating these factors, you can select the most suitable frequency converter for your needs, thereby improving production efficiency, reducing energy consumption, and ensuring the long-term stable operation of your equipment.

If you need further assistance or advice, feel free to contact Anyhz Drive. Our professional team is always ready to provide you with comprehensive technical support and services.

Contact Us

Contact Us