News

Site Editor

Site

https://cdn.anyhz.com/uploads/image/653decbc2fb16.png

Power quality management is a critical aspect of modern electrical systems, particularly in industries that rely on precise and stable power supply to maintain their operations.

Site

https://cdn.anyhz.com/uploads/image/653decbc2fb16.png

Power quality management is a critical aspect of modern electrical systems, particularly in industries that rely on precise and stable power supply to maintain their operations.

What Role Do Frequency Converters Play in Power Quality Management?

Views: 1780

Author: Site Editor

Publish Time: 2024-09-23

Origin: Site

Power quality management is a critical aspect of modern electrical systems, particularly in industries that rely on precise and stable power supply to maintain their operations. Frequency converters, also known as variable frequency drives (VFDs), play a pivotal role in ensuring optimal power quality by controlling the frequency and voltage supplied to electrical equipment. This article explores the key functions of frequency converters in power quality management and their impact on the overall efficiency and reliability of power systems.

Understanding Power Quality

Power quality refers to the stability and consistency of the electrical power supplied to end-users. It encompasses various factors such as voltage stability, frequency stability, harmonic distortion, and power factor. Poor power quality can lead to equipment malfunction, increased energy consumption, and even damage to electrical infrastructure. As industries become more reliant on sophisticated machinery and automation, maintaining high power quality has become increasingly important.

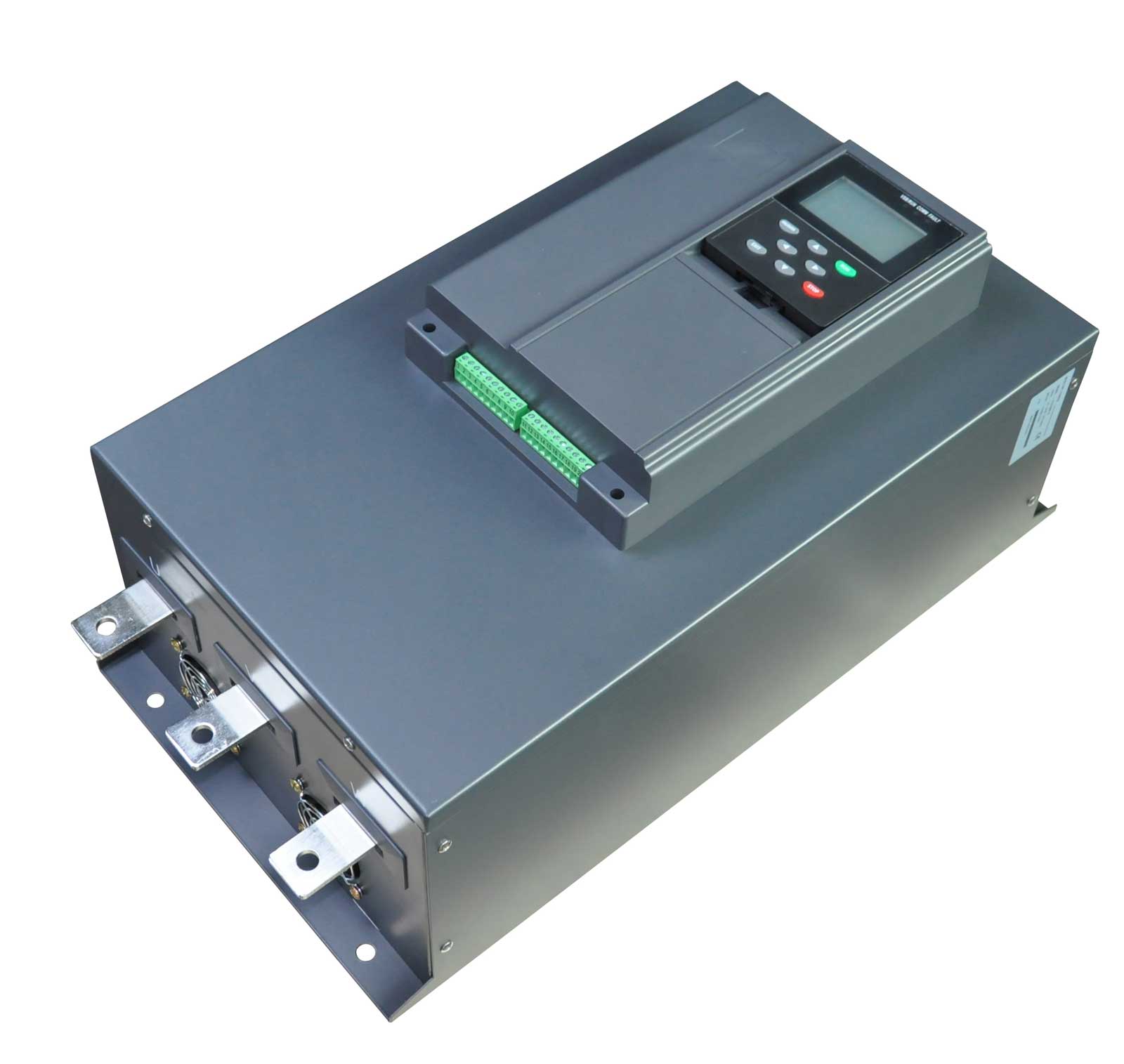

The Basics of Frequency Converters

A frequency converter is a device that adjusts the frequency and voltage of the power supplied to an electric motor or other load. By varying the frequency, the speed of the motor can be precisely controlled, allowing for more efficient operation. Frequency converters consist of three main components: a rectifier, a DC link, and an inverter. The rectifier converts the incoming AC power to DC, the DC link stabilizes the DC power, and the inverter converts the DC back to AC at the desired frequency and voltage.

Frequency Converters and Voltage Regulation

One of the primary roles of frequency converters in power quality management is voltage regulation. In electrical systems, voltage fluctuations can occur due to sudden changes in load or other disturbances. These fluctuations can lead to equipment malfunctions and reduced efficiency. Frequency converters help mitigate voltage variations by providing a stable output voltage, regardless of input voltage fluctuations. This is achieved by continuously adjusting the frequency and voltage supplied to the load, ensuring that the equipment operates within its optimal voltage range.

Harmonic Mitigation

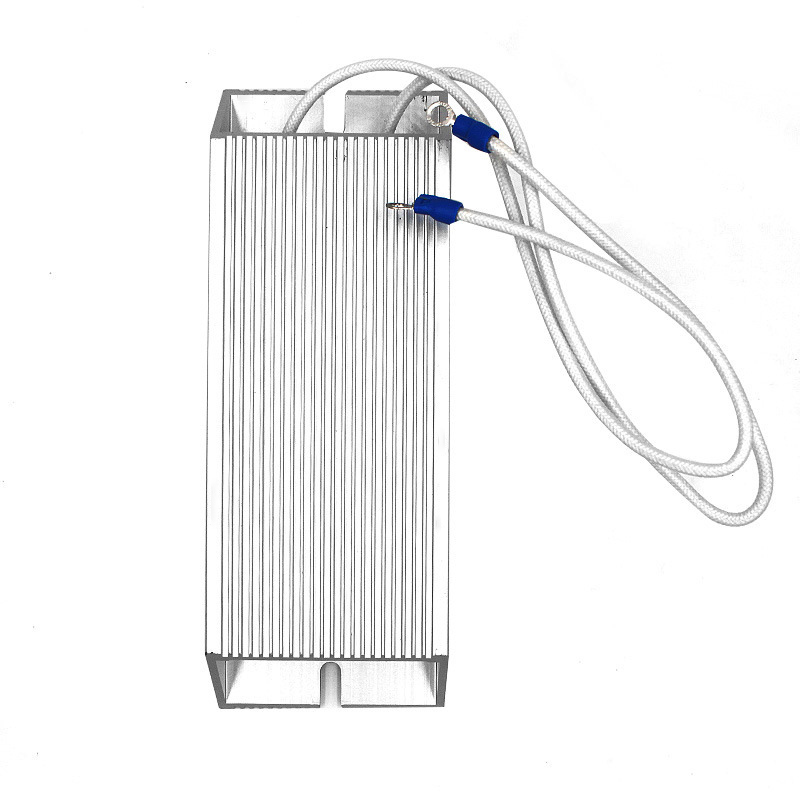

Harmonics are voltage or current waveforms that deviate from the fundamental frequency, leading to distorted power signals. Harmonic distortion can cause a range of issues, including overheating of equipment, increased losses in electrical systems, and interference with communication systems. Frequency converters are equipped with harmonic filters that reduce the harmonic content of the power supplied to the load. By filtering out these unwanted frequencies, frequency converters help maintain the integrity of the power supply and prevent the negative effects of harmonic distortion on equipment and systems.

Power Factor Correction

Power factor is a measure of how effectively electrical power is being used. A low power factor indicates that the electrical system is not efficiently utilizing the power supplied to it, leading to increased energy consumption and higher operating costs. Frequency converters can improve the power factor by controlling the phase angle between the voltage and current in the system. By optimizing the power factor, frequency converters reduce energy losses and enhance the overall efficiency of the electrical system.

Energy Efficiency and Cost Savings

The ability of frequency converters to precisely control motor speed and torque contributes to significant energy savings. In many industrial applications, motors are often operated at full speed even when full power is not required. Frequency converters allow motors to operate at lower speeds when less power is needed, reducing energy consumption and lowering operating costs. Additionally, the improved power quality achieved through the use of frequency converters can lead to longer equipment lifespan and reduced maintenance costs, further contributing to overall cost savings.

Enhanced System Reliability

Frequency converters enhance the reliability of power systems by preventing disturbances such as voltage sags, surges, and transients from affecting sensitive equipment. By providing a stable and controlled power supply, frequency converters minimize the risk of equipment failure and downtime. This is particularly important in critical applications where even a brief interruption in power can have significant consequences.

Conclusion

Frequency converters play a crucial role in power quality management by providing voltage regulation, harmonic mitigation, power factor correction, and energy efficiency. Their ability to enhance the stability and reliability of power systems makes them an essential component in modern industrial applications. As industries continue to demand higher levels of power quality and efficiency, the importance of frequency converters in maintaining optimal power performance will only continue to grow.

Anyhertz has been committed to the development, production and sales of frequency converters and related electrical transmission systems.

Contact Us

Contact Us