News

Site Editor

Site

https://cdn.anyhz.com/uploads/image/653decbc2fb16.png

Human-Machine Interface (HMI) display screens are essential tools in modern industrial and commercial settings.

Site

https://cdn.anyhz.com/uploads/image/653decbc2fb16.png

Human-Machine Interface (HMI) display screens are essential tools in modern industrial and commercial settings.

How Can HMI Display Screens Enhance Process Efficiency and Productivity?

Views: 1741

Author: Site Editor

Publish Time: 2024-09-16

Origin: Site

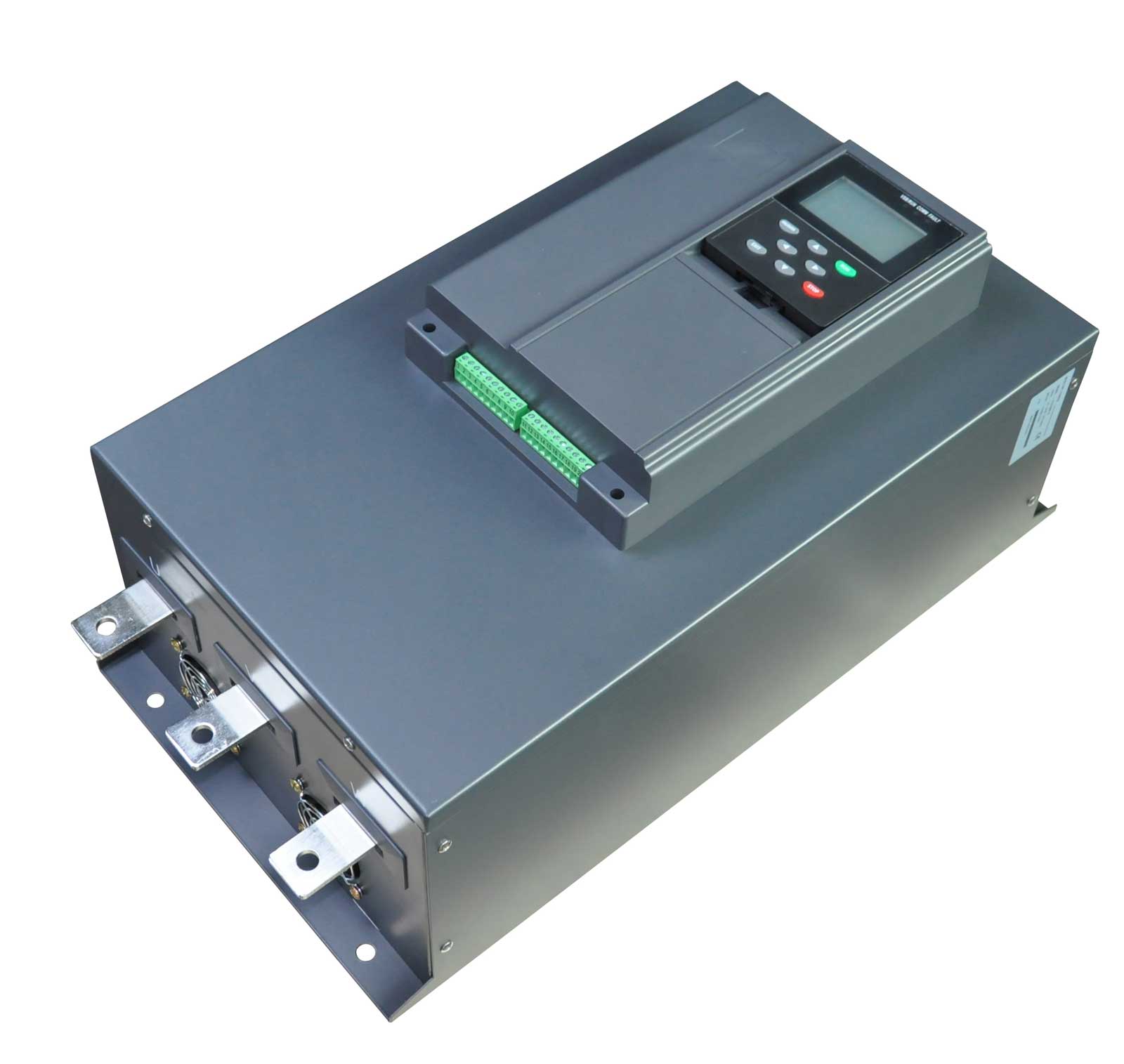

Human-Machine Interface (HMI) display screens are essential tools in modern industrial and commercial settings. These interactive screens facilitate the interaction between operators and machines, providing real-time data visualization, control, and diagnostics. As industries strive for greater efficiency and productivity, HMI display screens have become indispensable. This article explores how HMI display screens can significantly enhance process efficiency and productivity across various applications.

1. Real-Time Monitoring and Data Visualization

HMI display screens provide operators with real-time monitoring and data visualization capabilities. By displaying critical process parameters, such as temperature, pressure, flow rates, and motor speeds, operators can quickly assess the status of operations. This immediate access to data allows for timely decision-making, reducing the likelihood of errors and ensuring that processes run smoothly. Real-time monitoring also helps identify deviations from optimal operating conditions, enabling quick corrective actions to maintain efficiency.

2. Improved Process Control

HMI screens enhance process control by offering intuitive interfaces for managing and adjusting operational parameters. Operators can easily start, stop, and adjust machinery using touchscreens or other input methods. This ease of control minimizes the learning curve for new operators and reduces the risk of operational mistakes. Improved process control leads to more consistent and reliable production, enhancing overall productivity.

3. Enhanced Diagnostics and Troubleshooting

One of the key advantages of HMI display screens is their ability to provide detailed diagnostics and troubleshooting information. When an issue arises, the HMI can display error codes, alarm messages, and diagnostic data, helping operators quickly identify and address the problem. This capability reduces downtime by speeding up the troubleshooting process and minimizing the impact of equipment failures on production. Enhanced diagnostics also support preventative maintenance efforts, allowing for proactive identification and resolution of potential issues before they escalate.

4. Streamlined Workflow and Automation

HMI display screens facilitate the integration of automation systems, streamlining workflows and reducing manual intervention. By automating repetitive and time-consuming tasks, HMI systems free up operators to focus on more value-added activities. This automation reduces the risk of human error, improves consistency, and increases overall production speed. Streamlined workflows result in higher throughput and more efficient use of resources.

5. Customizable Interfaces and User Experience

Modern HMI display screens offer customizable interfaces that can be tailored to specific applications and user preferences. Customization options include color schemes, layout designs, and data presentation formats. A user-friendly interface enhances operator experience, making it easier to navigate and interpret information. Customizable HMIs also allow for the integration of specific operational requirements, ensuring that the interface meets the unique needs of each process. Improved user experience translates to higher efficiency and productivity, as operators can perform their tasks more effectively.

6. Data Logging and Analysis

HMI systems often include data logging and analysis capabilities, enabling the collection and storage of historical process data. This data can be analyzed to identify trends, patterns, and areas for improvement. By leveraging data analytics, businesses can optimize processes, reduce waste, and enhance overall efficiency. Data-driven decision-making supports continuous improvement efforts, leading to sustained productivity gains over time.

7. Enhanced Communication and Collaboration

HMI display screens can enhance communication and collaboration among team members by providing a centralized platform for sharing information. Operators, supervisors, and maintenance personnel can access the same real-time data and diagnostic information, facilitating better coordination and teamwork. Enhanced communication reduces misunderstandings and ensures that everyone is aligned with the current operational status and priorities. Improved collaboration leads to faster problem resolution and more efficient process management.

8. Remote Monitoring and Control

Advancements in HMI technology have enabled remote monitoring and control capabilities. Operators can access HMI systems from remote locations using computers, tablets, or smartphones. This remote access allows for real-time monitoring and control of processes, even when operators are not physically present on-site. Remote capabilities enhance flexibility, enabling quick responses to issues and adjustments to operations from anywhere. Remote monitoring also supports off-site supervision and management, contributing to overall process efficiency.

9. Compliance and Reporting

HMI display screens can assist with compliance and reporting requirements by automatically generating reports and maintaining records of operational data. These reports can be used to demonstrate compliance with industry standards, regulatory requirements, and internal quality control measures. Automated reporting reduces the administrative burden on operators and ensures accurate and timely documentation. Compliance with regulations and standards enhances operational integrity and reduces the risk of costly violations.

Conclusion

HMI display screens are powerful tools that enhance process efficiency and productivity through real-time monitoring, improved process control, enhanced diagnostics, streamlined workflows, customizable interfaces, data logging, enhanced communication, remote capabilities, and compliance support. By leveraging these capabilities, businesses can achieve greater operational efficiency, reduce downtime, and improve overall productivity.

As industries continue to evolve, the role of HMI display screens in optimizing processes and driving productivity will only grow in importance. Investing in advanced HMI solutions ensures that businesses remain competitive, agile, and capable of meeting the demands of modern industrial and commercial environments.

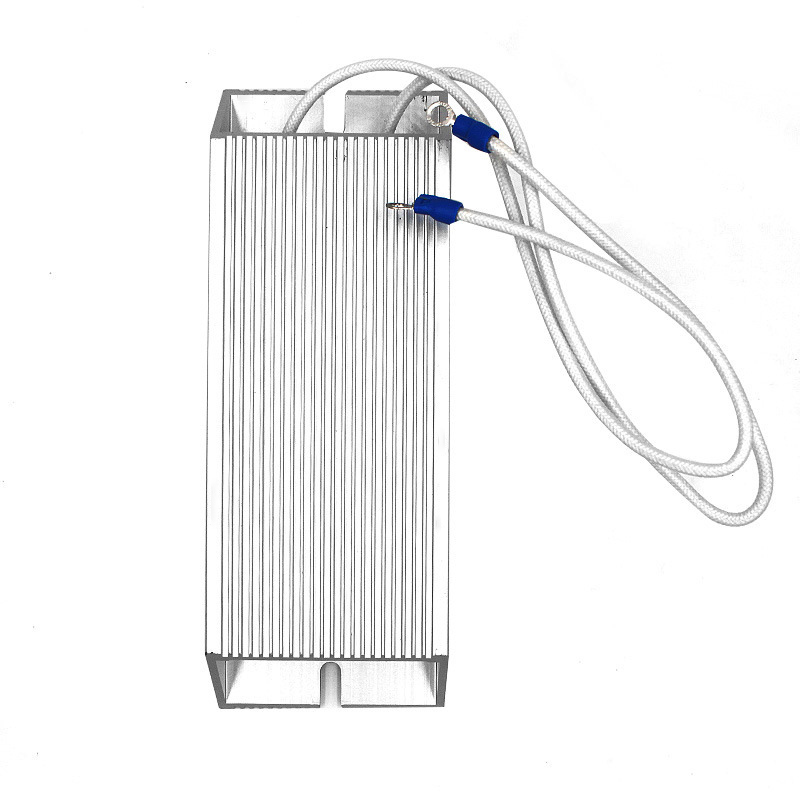

Anyhertz Drive as a leading manufacturer of high-end magnetic flux vector frequency converters, we are committed to providing advanced inverter cabinets that enhance system performance and drive operational excellence. By partnering with a trusted OEM, businesses can achieve greater efficiency, reliability, and longevity in their inverter-driven systems.We look forward to becoming your loyal friend and partner, and creating a mutually beneficial and win-win future together

Contact Us

Contact Us